What does HC Individual represent? It translates into personal advice throughout the entire product life cycle. It stands for individual attention from the first contact right through to various consultations. With HC Individual, we at Hillebrand Coating promise you a coating solution that is tailored to your needs and offers economic advantages.

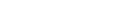

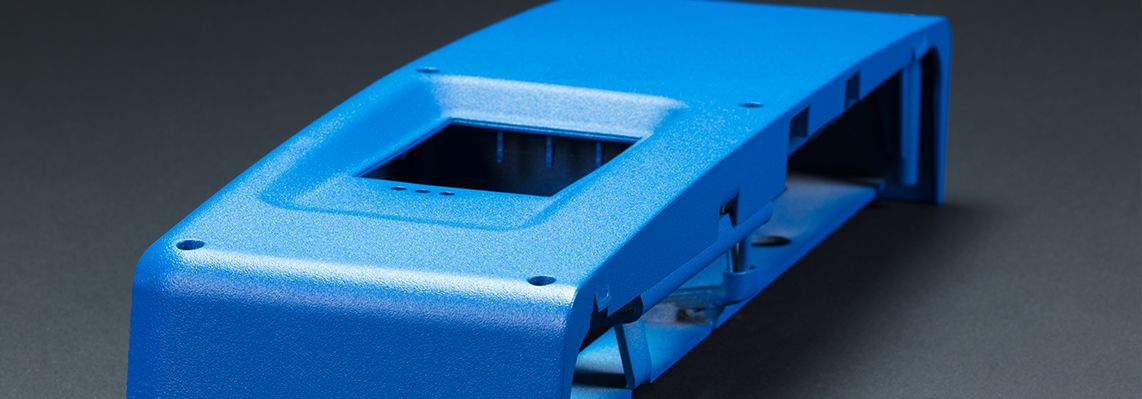

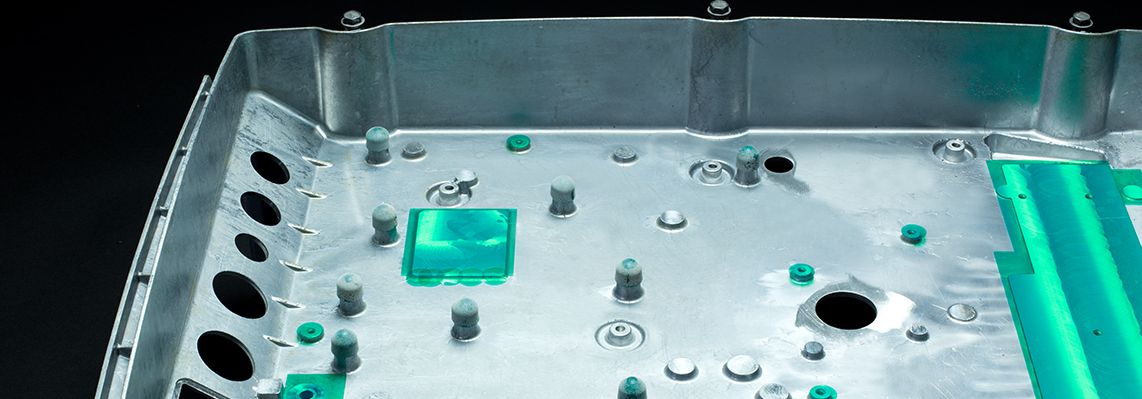

In the sector DECORATIVE, we take on many different tasks as part of HC Individual. The most important one is the realisation of your coating requirements using an economic mass production process. We use our many years of expertise and our extensive know-how. This allows us to implement high-quality projects at reduced costs - even if this hadn’t been deemed feasible during the initial inquiry.

Below, you will find HC Individual model for the business sector DECORATIVE.